Non-dispersive infrared sensor attenuates gasoline pollution

Contents

The Problem

How it Works

IR source

Test Trials Upcoming

Vapor recovery systems on today's gas pumps are in need of assistance and Marconi Commerce Systems (Greensboro, NC) is preparing to provide it.

The company has developed a non-dispersive infrared (NDIR) spectroscopic vapor-sensor monitor that can retrofit into existing gasoline-pump hoses. Its heart is the foil-filament pulsIR light source from Waltham, MA-based Ion Optics (Figure 1).

Today, to eliminate hydrocarbon emissions while refueling, most gasoline pumps come with a device that draws the exiting vapors from the car's fuel tank and directs them into the underground gasoline-storage unit.

One of the more common systems is the VaporVac. During vehicle refueling, a vacuum created by a motor-driven vapor pump pulls exiting vapors through intake holes near the nozzle tip. These gaseous hydrocarbons flow up the hose and into the underground gasoline storage tank. Electronics control the speed of the vapor pump to ensure that the vapor travels to the storage tank at a rate proportional to the flow of fuel.

The Problem (Back to Top)

A hitch arose when the U.S Environmental Pollution Agency (EPA) required 100% of all model-year-2000 passenger cars to come equipped with on-board refueling vapor-recovery (ORVR) systems. This device cleans vapors in the car's fuel tank by passing them through a carbon filter.

Although this may appear to be a great for the environment, it creates a problem at the pump. Cars outfitted with an ORVR canister emit so few hydrocarbons that the VaporVac recovery system draws only air. When this clean air is returned underground, the gasoline in the storage tank further evaporates to maintain an equilibrium with the partial pressure of its vapor, increasing the total vapor pressure above the gasoline. The tank vents this pressure through its chimney, releasing hydrocarbons into the atmosphere, thereby defeating the purpose of the ORVR.

To offset this occurrence, Marconi developed a sensor to detect when the air is "clean" and when it is "dirty." With hydrocarbons present, the system acts normally. When HCs are absent, the sensor signals the vacuum pump to shut down.

How it Works (Back to Top)

Marconi initially looked at various optical sensors but they couldn't withstand the harsh environment, says Steve Robertson, Vapor Recovery Product Manager at Marconi.. Then the company decided to develop a non-dispersive infrared (NDIR) spectroscopic gas sensor, which does not need being in direct contact with the environment being tested.

Most gases have a unique infrared absorption signature in the 2 to 14 µm region, says Brian Kinkade, vice president of marketing and sales at Ion Optics. The signatures conclusively identify the chemicals in liquid and gas-phase mixtures.

A simple NDIR sensor consists of an IR light source, a sample compartment of known optical length, an optical filter, and an IR detector with its associate electronics. The IR emitter produces broadband IR illumination. Spectral filters restrict the view of the IR detector to the desired wavelength.

For the device designed for the VaporVac system, engineers employed a dual-channel pyroelectric detector manufactured by Eltec Instruments, which contains integral precision bandpass filters--one at 3.4 µm, which wavelength is absorbed by the hydrogen-carbon bond, and a second at 4.0 µm that serves as a reference channel.

As the target gas passes through the sampling chamber, the ratio of 3.4 µm and 4.0 µm reading is measured, yielding the hydrocarbon concentration. "The combination of the Ion Optics source and Eltec Instruments detector greatly simplifies the design of an accurate and reliable NDIR measurement system," says lead engineer Edward Payne of Marconi.

IR source (Back to Top)

Made from a thin foil filament, the pulsIR source reportedly achieves greater than 82% intensity modulation for pulse rates of less than 2 Hz.

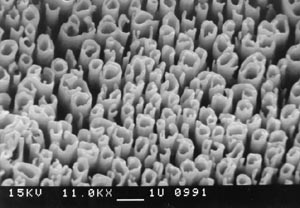

To improve the filament's infrared emission, engineers treat the surface with ion milling which creates random surface texture of sub-micron-scale rods and cones (Figure 2). This "tubeworm" texture modifies the reflection and absorption spectra relative to that from a flat filament of the same material.

The high emissivity of the ion-beam-treated "radiator" surface provides rapid cooling via thermal radiation, while still providing significant in-band illumination over a desired band in the 2- to 20-µm region. This design therefore allows the pulsIR to operate with package temperatures below the ignition levels of gasoline vapors, an important design consideration.

For wavelengths small compared with the size of the radiator's features, the tube-like surface scatters most incoming light. Therefore it has low reflectivity and the filaments appear visibly black. Being a blackbody, it has high emissivity--greater than 80%. For wavelengths long compared with feature size, the surface looks like flat metal and, characteristic of a flat metal, has low emissivity.

Test Trials Upcoming (Back to Top)

"We are going to test the device this September and hope to get California Air Resources Board (CARB) certification at that time," says Robertson. CARB is the national standard for vapor recovery systems. Once certified, the Marconi system will be retrofitted into existing gasoline service pump stations by breaking the vapor-return retention line on either side of the gas pump. The company also will build new pumps already equipped with the IR sensor. "This is only the first in a series of requirements that will be coming on line for vapor recovery at gasoline pumps," says Robertson.

About the author…

Laurie Toupin is a freelance writer based in Massachusetts. (Back to Top)