Mercury Removal

Tri-Mer’s UltraCat ceramic filter system is compatible with standard mercury removal techniques. Control of mercury is notoriously difficult: each instance is analyzed individually and customized solutions are engineered. A few general observations can be offered, however.

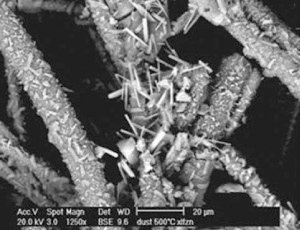

- The catalytic filters can handle very high particulate loads while maintaining exceptionally low outlet levels.

- Just as the addition of dry sorbents for the removal of acid gases is effective, so is the addition of powdered activated carbon (PAC) for mercury.

- In general, regular PAC becomes less effective with temperature, topping out around 400°F. The chemical composition of the pollutant gas plays a major role; hence, the difficulty of blanket statements.

- At higher temperatures, brominated PAC is required. According to the manufacturers of brominated products, temperatures of 500°F to 800°F are acceptable.

- Significant levels of mercury removal have also been achieved with injected powdered trona.

- Many new sorbents for mercury removal have been introduced in recent years; some of these appear very promising.

The nano-catalyst used for NOx removal also breaks down dioxins. Optimum dioxin control is limited to an upper temperature of 500°F if there are constituents such as chlorine, fluorine, and other halides that can lead to re-formation of the dioxin. If these have largely been removed upstream in the injection of dry sorbent, permanent dioxin destruction will occur at higher temperatures as well. Within a wide range, destruction efficiency is typically 97% to 99%.