CO-combustible Measurement

Incomplete combustion results in combustibles, consisting of hydrogen (H2) and carbon monoxide (CO), in the flue gas.

Among the prevalent methods for on-line monitoring of CO in flue gas is non-dispersive infrared absorption.

Extractive Infrared CO Analyzers

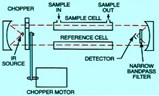

Extractive infrared CO analyzers (Figure 1) have the infrared source, detector, and optics in a single package that mounts away from the stack. They are used primarily in emissions-monitoring systems and usually are located at easily accessible places near the combustion process.

Figure 1. Extractive infrared CO analyzer

The infrared light from a thermal source is mechanically chopped and then alternately passed through a cell containing the sample gas and a sealed cell containing air. If CO is present in the sample gas, some of the infrared energy is absorbed by the sample cell. The remaining infrared energy then passes through a narrow bandpass filter that blocks all radiation not in the 4.5- to 4.7-micron range.

This filtered energy is focused on a thermal detector that generates an electric signal related to the intensity of the radiation. The ratio of the two alternating signals is a direct measure of the CO concentration in the sample gas. Electronic circuitry can provide an analog or digital display of the CO value as well as a current or voltage output signal suitable for a recorder or control system.

For extractive infrared CO-analyzer use in field installations, flue gas is drawn through a sampling probe inserted into the stack or duct. In most cases, sample conditioning is required to clean, dry, and cool the sample before it enters the analyzer. Provisions for the introduction of calibration gases are usually an integral part of the design of the sample-conditioning system.

Across-the-Stack Systems

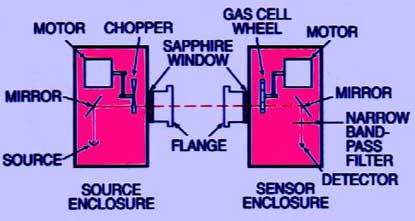

In across-the-stack infrared CO analyzers, the infrared source is housed in an enclosure that mounts directly on the stack or duct (Figure 2).

Figure 2. Across-the-stack infrared CO analyzer

The infrared beam generated by the source passes completely through the stack into a similar enclosure mounted on the stack's opposite side. The beam usually is chopped mechanically in the source enclosure to differentiate it from the infra-red energy emitted by the hot interior stack walls. The infrared energy in the 4.5- to 4.7-micron band absorbed by any CO present in the flue gas is detected in the sensor enclosure and interpreted as CO.

For the CO interpretation, two physically identical sealed gas cells just ahead of the narrow bandpass filter and detector are alternately moved in and out of the infrared beam in the sensor enclosure. One cell contains a high concentration of CO that totally absorbs infrared energy at the CO-sensitive wavelengths. The other cell contains only nitrogen.

The difference between the two signals generated by the infrared detector is inversely proportional to the energy absorbed by any CO in the flue gas. Correlation methods are used to solve Beer's Law* and thus calculate CO concentration.

The intensity of the infrared beam transmitted across the stack may vary due to decay of the thermal source, a darkening of the enclosure windows by soot, or particulates in the stack. A standard signal-processing technique, however, ensures that the final result is independent of any changes in light intensity.

This technique involves dividing the difference between the two gas-cell signals by their sum. The result is a signal that is insensitive to transmitted light changes, varying only with the concentration of CO in the flue gas. Electronic circuitry conditions the signal for display on a meter and for a recorder or control-system output.

Comparing Systems

Across-the-stack CO systems have two major advantages compared with extractive CO systems.

- First, their response is significantly faster than off-stack analyzers, which take several minutes to respond to a change in flue-gas conditions.

- Second, across-the-stack systems measure the average CO concentration in the stack—unlike off-stack analyzers, which sample from a single point. Across-the-stack systems are unaffected by stratification or stagnation of the flue gas in the stack and provide a good average of the CO level.

Extractive CO analyzers may have the advantage of lower installation costs than across-the-stack CO analyzers because the measuring system can be located at ground level, whereas across-the-stack systems must be mounted on the stack or duct. However, the lower installation cost may be offset by the cost and maintenance of a sampling system.

Another advantage of extractive CO analyzers is their ability to be calibrated with known calibration gas mixtures. However, some across-the-stack analyzers use additional sealed gas cells containing known mixtures of CO to facilitate calibration.

Both across-the-stack and extractive CO systems, however, are inferior to catalytic combustibles detectors.

Neither the extractive nor across-the-stack CO system can be placed in high-temperature areas close to the flame source, as can a catalytic combustibles detector. As a result, the combustible being measured may be adulterated.

Also both analyzers are considerably slower than are catalyst combustibles detectors.

* log (I/Io)=- c l, where

c l, where

Io is the intensity of the infrared light at a specific wavelength ( ) entering the sample; I is the intensity leaving the sample;

) entering the sample; I is the intensity leaving the sample;  is the absorption coefficient for CO at wavelength

is the absorption coefficient for CO at wavelength  ; c is the concentration of CO in the sample; and l is the path length of the infrared light beam through the sample. By holding the pathlength, 1, constant, the ratio I/Io becomes a direct measurement of the CO concentration.

; c is the concentration of CO in the sample; and l is the path length of the infrared light beam through the sample. By holding the pathlength, 1, constant, the ratio I/Io becomes a direct measurement of the CO concentration.

The previous article is adapted from an extract of the Combustion Efficiency Handbook developed by the technical staff Ametek, Thermox Business Unit, 150 Freeport Road, Pittsburgh, PA 15238.

Edited by Paul Hersch