Pollution Control and Solvent Recovery for the Pharmaceutical Industry

| Recover and Reuse | Treatment Applications |

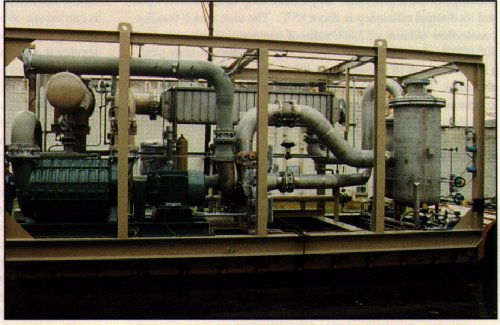

NUCON International, Inc. has developed and commercialized the reverse Brayton Cycle process to control pollution and recover solvents. Our BRAYSORB® and BRAYCYCLE® Solvent Recovery Systems (SRS) are the most reliable, efficient and cost effective systems available for most pharmaceutical applications.

The BRAYSORB® SRS uses an adsorbent bed to concentrate solvents and then "strips" them with dry nitrogen (not steam). The recovered solvents are pure and water free. There is no waste water stream requiring treatment. The BRAYCYCLE® SRS operates on direct condensation. Nothing is added to the process stream. Recovered solvents are clean and recyclable.

These systems are supplied skid mounted and factory checked out for ease of installation. They are automatically controlled by a PLC under supervision of an industrial computer. Any degree of data interchange and process interface desired by the client is easily provided by our experienced control engineers.

NUCON International Inc., 7000 Huntley Road, P.O. Box 29151, Columbus, OH 43229-1022. Tel: 614-846-5710; Fax: 614-431-0858.