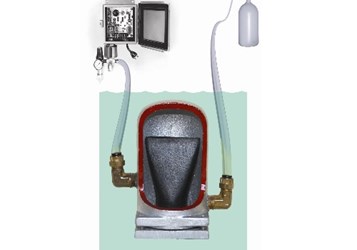

Automatic Duckbill Composite Sampling System

This unique composite sampler helps municipal & industrial plants automate composite sampling of tanks, sumps, open channels & sewers, and monitor process slurries and effluent.

The system uses compressed air and the rubber Duckbill, acting as a check valve, to collect samples. It is inherently explosion-proof (no pump; no vacuum system). Complete samples can be moved up high lifts (more than 79ft/24m vertically) and over long runs (more than 98ft/30m horizontally), even in freezing temperatures.

Liquid enters the submerged sampler head through the Duckbill. Each burst of compressed air squeezes the Duckbill closed in a self-cleaning action and forces a sample to the collection bottle. Lines are blown clear and dry after each sample.

The controller can be located far from the sampling site. Users program it to sample based on time or by a flow meter, and can collect from multiple sites simultaneously, facilitating the monitoring required for environmental regulatory compliance.

Source: Markland Specialty Engineering